+86-576-88024290

Search

07 11, 2025

Industry Updates

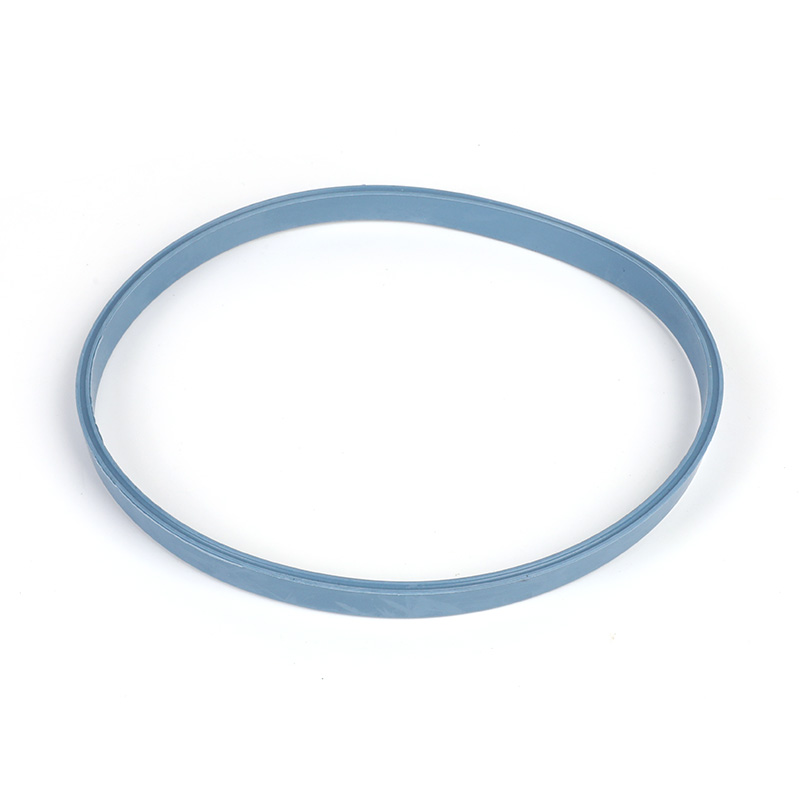

Modern vehicles rely heavily on efficient lubrication systems to ensure smooth engine operation. One often overlooked component contributing to this efficiency is the Automobile Oil Filter Seals. These seals play a crucial role in maintaining a secure connection between the oil filter and the engine block, preventing leaks and ensuring consistent oil flow. By providing a tight barrier, they help maintain engine oil pressure, which is essential for proper lubrication of moving parts and for extending engine life.

Oil filter seals are designed to withstand high temperatures and pressures within the engine. When the engine runs, oil circulates rapidly, passing through the filter to remove impurities. If the Automobile Oil Filter Seals are damaged or improperly installed, oil can leak, reducing the overall efficiency of the lubrication system. This not only affects the performance of the engine but can also advance to increased wear on critical components, such as pistons, bearings, and camshafts. High-quality seals ensure that oil remains in the intended pathway, allowing the filter to do its job effectively.

In addition to oil filter seals, Oil Pump Seals are another vital component in modern lubrication systems. The oil pump is responsible for moving oil throughout the engine, and the seals help maintain the proper pressure and prevent leakage at pump connections. When Oil Pump Seals are functioning correctly, they contribute to a consistent oil supply, ensuring that every moving part receives adequate lubrication. This reduces friction, prevents overheating, and lessens the risk of engine failure caused by inadequate lubrication.

The performance of both Automobile Oil Filter Seals and Oil Pump Seals largely depends on the materials used. Seals are typically made from durable rubber or synthetic compounds that can resist degradation from high temperatures, pressure, and chemical exposure from engine oil. Selecting materials with the right balance of flexibility and strength is crucial, as this allows the seals to maintain a tight fit even under bad engine conditions. Using seals made from inferior materials can advance to early wear, oil leaks, and reduced lubrication efficiency.

Regular maintenance of seals is essential for sustaining lubrication efficiency. During routine oil changes, it is advisable to inspect Automobile Oil Filter Seals for any signs of cracks, hardening, or deformation. Similarly, Oil Pump Seals should be examined for leaks or wear. Replacing worn or damaged seals promptly prevents oil loss and protects the engine from unnecessary stress. Proper installation of new seals is also important; even a minor misalignment can compromise the seal’s effectiveness and result in oil leakage.

By ensuring proper lubrication, seals indirectly contribute to engine longevity. Engines with well-maintained Automobile Oil Filter Seals and Oil Pump Seals experience less friction, reduced heat buildup, and more stable oil pressure. These factors collectively minimize component wear and reduce the risk of breakdowns. Over time, maintaining seals in good condition can advance to improved reliability and smoother operation of the vehicle, demonstrating their significance in the overall engine system.

While often small and overlooked, Automobile Oil Filter Seals and Oil Pump Seals play an essential role in modern vehicle lubrication systems. They ensure that oil flows efficiently, maintain pressure, and prevent leaks, all of which are critical for engine performance and durability. Paying attention to the condition of these seals during routine maintenance can have a notable impact on the reliability and longevity of a vehicle’s engine. In modern vehicles, effective lubrication begins with the integrity of these small yet essential components