+86-576-88024290

Search

20 06, 2025

Industry Updates

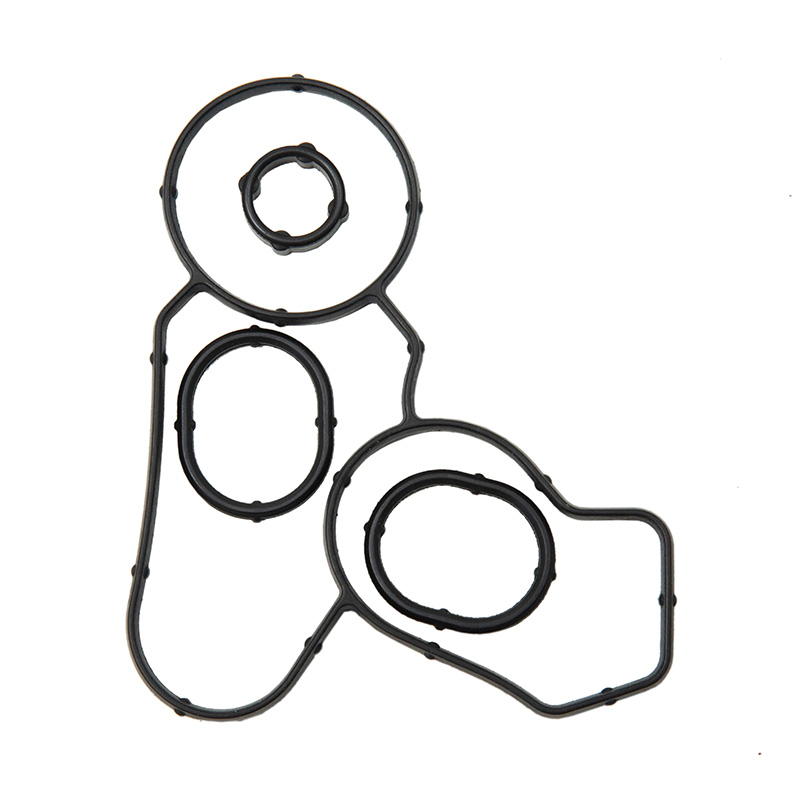

Within the complex symphony of industrial machinery, two critical systems stand out for their reliance on precision and reliability: hydraulics and lubrication. At the very heart of these systems, ensuring their efficient and safe operation, lies a component often overlooked but absolutely vital: Oil Pump Seals. These unassuming guardians perform a relentless, high-stakes duty, preventing catastrophic leaks and maintaining the integrity that keeps massive forces under control and delicate components smoothly gliding. Understanding the indispensable role of Oil Pump Seals in both hydraulic and lubrication contexts reveals their true engineering significance.

Hydraulic Systems: Containing the Power

Hydraulic systems are the muscle of modern industry. From the immense clamping force of an injection molding machine shaping plastic components, to the precise movements of CNC machine tools, the powerful lifting of excavator arms on a construction site, or the controlled pressure exerted by massive stamping presses, hydraulics translate fluid power into formidable mechanical action. Central to this power transfer are hydraulic pumps – gear pumps, vane pumps, and piston pumps – tasked with generating the high-pressure fluid flow.

This is where Oil Pump Seals become non-negotiable. Hydraulic pumps operate under pressures, often reaching hundreds or even thousands of PSI. Any leakage at the pump shaft, where it rotates within the housing, represents a direct loss of system pressure, the very essence of hydraulic power. Compromised Oil Pump Seals to diminished force output, sluggish machine response, and reduced overall efficiency. More critically, leaking high-pressure hydraulic oil poses severe safety hazards (fire risk, slippery surfaces) and environmental contamination concerns. Robust, precisely engineered Oil Pump Seals are the primary barrier preventing this high-energy fluid from escaping. They maintain the system pressure crucial for performance, protect personnel and the environment, and prevent costly fluid loss. The selection of appropriate Oil Pump Seals for hydraulic pumps considers pressure rating, fluid compatibility, shaft speed, and temperature s – factors paramount to sustained, safe operation. Regular inspection and timely replacement of hydraulic pump Oil Pump Seals are fundamental maintenance practices.

Lubrication Systems: Delivering the Lifeblood

While hydraulics provide force, lubrication systems provide longevity. They are the circulatory system for countless machines, delivering oil to critical friction points like gearbox meshes, large bearing assemblies, and engine components. Centralized lubrication systems, common in heavy machinery and manufacturing lines, use pumps to distribute precise amounts of lubricant from a central reservoir to numerous points. Similarly, integral oil pumps within gearboxes or dedicated bearing lubrication units ensure a constant protective film.

Here, the function of Oil Pump Seals shifts subtly but remains equally critical. Lubrication pumps typically operate at lower pressures than hydraulic pumps. However, the consequences of seal failure are no less severe. Leaking Oil Pump Seals in a lubrication system directly cause lubricant starvation at the delivery points. Insufficient oil flow s to increased friction, accelerated wear, overheating, and ultimately, catastrophic bearing failure or gear damage. This translates to unplanned downtime, expensive component replacements, and lost production. Furthermore, leaking lubricant creates a mess, potential slip hazards, and environmental issues. Effective Oil Pump Seals ensure that every drop of expensive lubricant is delivered exactly where it's needed, maintaining the vital oil film that separates moving parts. They prevent external contaminants like dirt, dust, and moisture from being drawn into the pump and subsequently into the sensitive lubrication circuit, which can cause abrasive wear and oil degradation. Choosing the right Oil Pump Seals for lubrication pumps involves factors like oil viscosity, chemical compatibility, shaft speed, and resistance to ingress of contaminants. Maintaining the integrity of lubrication pump Oil Pump Seals is essential for achieving equipment lifespan and operational reliability.

Shared Challenges, Critical Solutions

Despite their different operational pressures, Oil Pump Seals in both hydraulic and lubrication applications face common enemies:

Friction and Heat: The constant friction at the seal-shaft interface generates heat. Oil Pump Seals must withstand this heat without degrading, hardening, or losing elasticity.

Wear: Continuous shaft rotation causes wear on the sealing lip or face. High-quality materials and designs in Oil Pump Seals are essential for longevity.

Chemical Compatibility: Hydraulic fluids and lubricants vary widely in formulation. Oil Pump Seals must be chemically resistant to the specific fluid they contain, preventing swelling, cracking, or dissolution.

Pressure and Vacuum: Hydraulic seals face high internal pressure trying to force fluid out. Lubrication pump seals might experience suction (vacuum) on the inlet side. Oil Pump Seals must be designed to handle these pressure differentials without leaking or collapsing.

Contamination: Abrasive particles in the fluid can score shafts and damage seal surfaces. Effective filtration protects Oil Pump Seals, but the seals themselves must offer some resilience.

Modern Oil Pump Seals are sophisticated components. Materials range from nitrile rubber (NBR) for general purposes to fluoroelastomers (FKM/Viton) for high temperatures and aggressive fluids, polyacrylate (ACM), or PTFE-based compounds. Designs include simple lip seals, more complex spring-energized seals, and mechanical seals for the demanding high-pressure or high-speed hydraulic applications. The selection of the correct type and material of Oil Pump Seals is a critical engineering decision impacting system performance and cost of ownership.

Oil Pump Seals are far more than simple gaskets or afterthoughts. In hydraulic systems, they are the essential containment technology that allows immense forces to be harnessed safely and efficiently. Without reliable Oil Pump Seals, hydraulic power dissipates, performance plummets, and hazards escalate. In lubrication systems, they are the guarantors of precise oil delivery, the protectors against contamination, and the silent partners in preventing catastrophic wear and extending machinery life. Leaking Oil Pump Seals directly undermine the core function of both systems.

Investing in high-quality Oil Pump Seals, specifying them correctly for the specific operating conditions (pressure, speed, temperature, fluid), and adhering to a proactive maintenance schedule for inspection and replacement are fundamental practices for any operation relying on hydraulic power or centralized lubrication. The performance and longevity of critical industrial assets – from molding machines and precision lathes to earthmovers and power generation turbines – are inextricably linked to the humble yet mighty Oil Pump Seal. They are the unsung heroes, the silent sentinels standing guard against leakage and failure, enabling the smooth, powerful, and enduring operation of the machinery that drives our industrial world. Recognizing the pivotal role of Oil Pump Seals is key to achieving operational excellence and cost-effective maintenance.