+86-576-88024290

Search

22 08, 2025

Industry Updates

In the intricate world of industrial machinery, where hydraulic systems and lubrication units form the backbone of operational efficiency, the role of oil pump seals cannot be overstated. These unassuming components are pivotal in preventing oil leakage and ensuring the seamless functioning of critical equipment. As industries continue to demand higher performance and reliability, the significance of oil pump seals has come to the forefront, driving innovation and enhancing maintenance practices.

The Critical Role of Oil Pump Seals in Industrial Operations

Industrial environments are characterized by their demanding conditions—high pressures, fluctuating temperatures, and continuous operation. Amidst this, hydraulic systems and lubrication units are essential for maintaining the fluidity and efficiency of machinery. However, these systems are only as reliable as their weakest link, and often, that link is the oil pump seals.

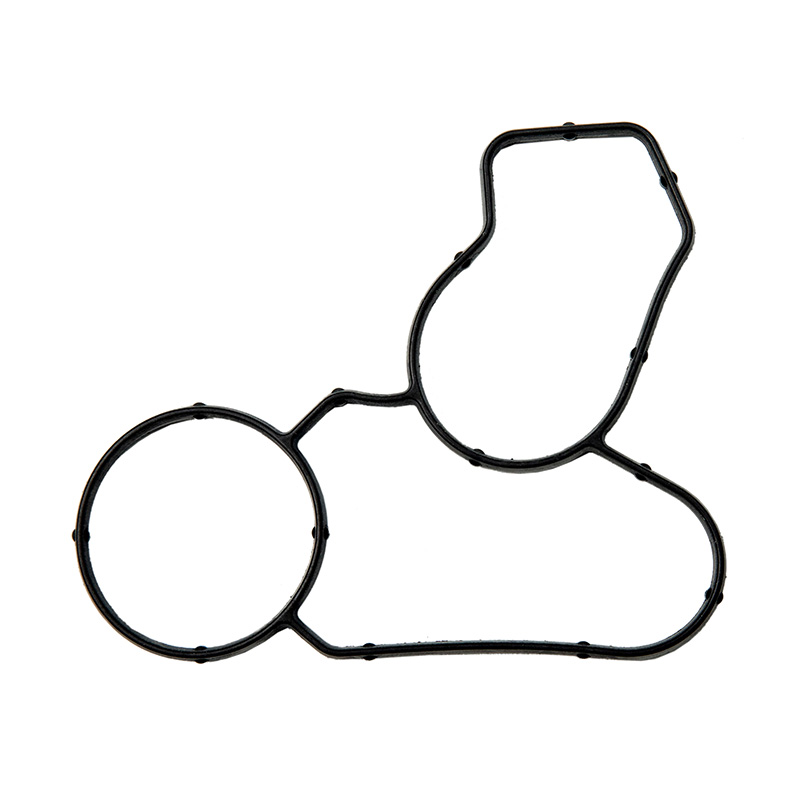

Oil pump seals are engineered to withstand the rigors of industrial applications. They are designed to prevent the escape of oil, which not only conserves valuable resources but also safeguards the surrounding environment from contamination. In hydraulic systems, where precise control of fluid dynamics is crucial, a compromised seal can to significant operational inefficiencies. Similarly, in lubrication systems, the failure of oil pump seals can result in inadequate lubrication, to increased wear and tear on machinery.

Material and Design Innovations

The effectiveness of oil pump seals hinges on their material composition and design. Modern oil pump seals are crafted from a variety of high-performance materials, including specialized rubbers and synthetic compounds, which offer resistance to oil, heat, and abrasion. These materials are chosen for their ability to maintain integrity under conditions, ensuring that the seals remain effective over extended periods.

Innovative design approaches have also enhanced the functionality of oil pump seals. Contemporary seals often feature multi-layer constructions, combining different materials to optimize performance. For instance, a seal might have a rubber exterior for flexibility and a metal core for structural strength. This composite design allows the seal to withstand high pressures and temperatures while maintaining a tight seal.

Maintenance and Longevity

The longevity of oil pump seals is a critical factor in the overall efficiency of industrial equipment. Regular maintenance is essential to ensure that seals remain in condition. This involves periodic inspections to check for signs of wear, such as cracks or deformations, and timely replacement of compromised seals. By adhering to a proactive maintenance schedule, industrial operators can significantly extend the life of their equipment and reduce the risk of unexpected failures.

Moreover, advancements in monitoring technologies have enabled more sophisticated maintenance practices. Sensors can now be integrated into oil pump seals to provide real-time data on their condition. This allows for predictive maintenance, where seals can be replaced before they fail, minimizing downtime and operational efficiency.

Environmental and Cost Benefits

The environmental impact of industrial operations is a growing concern, and oil pump seals play a crucial role in mitigating this impact. By preventing oil leaks, these seals help to reduce the amount of oil that enters the environment, protecting natural resources and complying with environmental regulations. Additionally, the prevention of oil leaks s to cost savings, as less oil is wasted and the need for frequent replacements is reduced.

As industries continue to evolve, so too must the components that support them. The future of oil pump seals is likely to be shaped by ongoing advancements in material science and manufacturing technologies. For instance, the development of new composite materials could further enhance the durability and performance of seals. Additionally, the integration of smart technologies, such as self-healing materials and advanced sensors, could revolutionize the way seals are monitored and maintained.

To illustrate the importance of oil pump seals, consider a large manufacturing plant that relies heavily on hydraulic presses. In this facility, the failure of a single oil pump seal led to a significant oil leak, causing the press to malfunction and resulting in a costly shutdown. The subsequent investigation revealed that the seal had deteriorated due to prolonged exposure to high temperatures and pressures. The plant's maintenance team replaced the compromised seal with a new, high-performance model and implemented a more rigorous inspection schedule. This change not only resolved the immediate issue but also led to a marked improvement in the overall reliability of the hydraulic system.

In the industrial landscape, where efficiency and reliability are paramount, oil pump seals stand as a testament to the importance of seemingly small components in the grand scheme of operations. By preventing oil leaks and ensuring the smooth operation of hydraulic and lubrication systems, these seals contribute significantly to the longevity and efficiency of industrial equipment. As industries continue to push the boundaries of performance, the ongoing development and optimization of oil pump seals will remain a crucial element in the pursuit of operational excellence.