+86-576-88024290

Search

23 05, 2025

Industry Updates

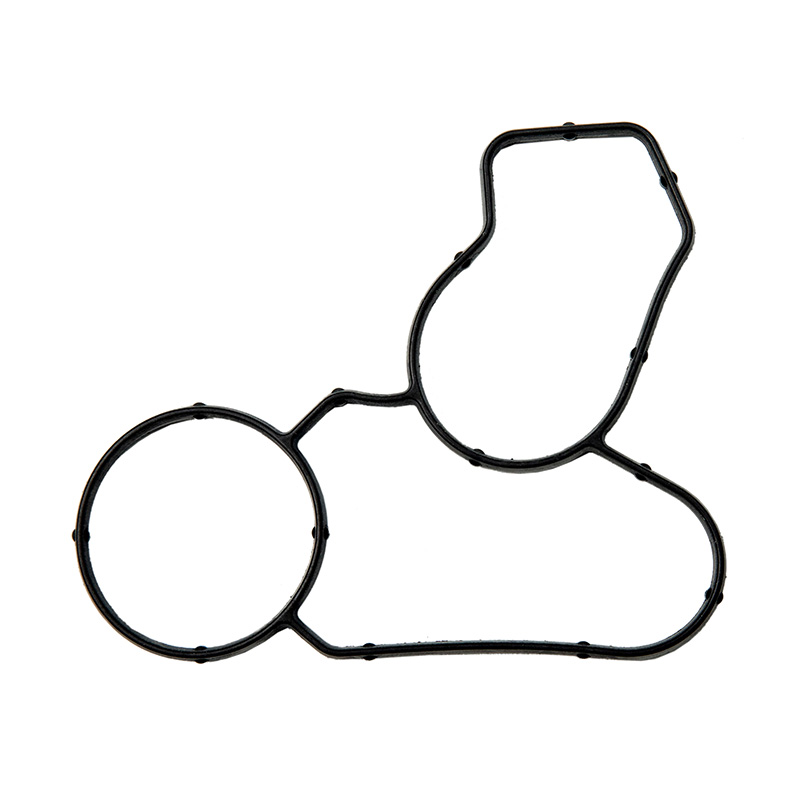

When it comes to maintaining the integrity and performance of engines, the role of oil pump seals often goes unnoticed. These small, yet crucial components ensure that an engine operates smoothly under certain conditions. Oil pump seals are integral to preventing oil leaks and maintaining the proper flow of lubrication throughout the engine. Their ability to withstand harsh chemicals and oils makes them essential in the highly demanding world of automotive, industrial, and marine applications. In this article, we will delve into the importance of oil pump seals, their resilience against oil and chemical corrosion, and why they are indispensable for long-lasting engine performance.

The Role of Oil Pump Seals

At the heart of any engine lies the oil pump, responsible for circulating oil throughout various moving parts. The oil pump seal is designed to keep the oil inside the pump and prevent it from leaking. These seals ensure that the oil remains contained under the pressure needed for effective lubrication, reducing the risk of engine wear, overheating, and malfunction. Without a properly functioning oil pump seal, the oil circulation would be disrupted, to inadequate lubrication, which can severely damage the engine.

In addition to sealing the oil within the pump, oil pump seals also help to maintain the efficiency of the entire lubrication system. The precise design of these seals guarantees that the oil is properly pressurized, preventing any air from entering the system, which could reduce the oil's effectiveness.

Resilience Against Oils and Chemicals

One of the remarkable characteristics of oil pump seals is their resistance to a wide variety of oils and chemicals. Whether it's lubricating oil, fuel additives, or cleaning solvents, oil pump seals are built to handle a range of substances that would quickly degrade other materials. This is particularly important in environments where the pump seal is exposed to aggressive substances, such as high-temperature oils, additives, and fuels.

The ability of oil pump seals to resist oil and chemical corrosion is essential for maintaining long-term engine performance. When exposed to harsh oils, fuels, and chemicals, inferior seals may break down, swell, or lose their ability to maintain a proper seal, to leaks or pump failure. High-quality oil pump seals, however, retain their structural integrity even in challenging environments, ensuring that the oil circulation remains uninterrupted.

In addition to being resistant to oils and fuels, oil pump seals must also endure exposure to high temperatures. Many engines operate in conditions where the oil can exceed 100°C (212°F), and the seals must be able to withstand these elevated temperatures without losing their sealing ability. High-performance oil pump seals are made from materials like fluorocarbon or nitrile rubber, which can withstand both high temperatures and harsh chemicals, ensuring that the engine operates optimally for years.

Application in Complex Chemical Environments

Oil pump seals are not only exposed to basic oils and fuels but are also subjected to various chemicals used in the automotive and industrial sectors. For instance, cleaning solvents and fuel additives can be corrosive to materials that aren’t specifically engineered to resist them. Oil pump seals that are designed to operate in these environments must be capable of withstanding prolonged exposure to these chemicals without deteriorating.

This ability to perform in complex chemical environments is one of the reasons why oil pump seals are used across so many different industries. Whether in the automotive, marine, or industrial sector, these seals are designed to maintain their integrity even in the presence of corrosive chemicals, ensuring that the engine or pump system operates without fail.

Durability and Maintenance Considerations

The durability of oil pump seals is a critical factor in reducing the need for frequent maintenance or replacement. Over time, seals can degrade due to wear and tear, exposure to temperatures, and chemical exposure. However, high-quality oil pump seals are designed to last for extended periods, withstanding these challenges without compromising performance.

Regular maintenance checks can help identify any early signs of wear or damage, such as oil leaks or reduced oil pressure, which could indicate that the oil pump seal is starting to fail. However, with the right seal material and design, oil pump seals can continue to perform effectively for years, minimizing the need for frequent repairs or replacements.

When choosing oil pump seals, it is essential to select the correct material and design based on the specific application and operating environment. Selecting the right oil pump seal for the job ensures that the engine remains well-lubricated, reducing the risk of damage and increasing the overall lifespan of the engine.

Oil pump seals are vital components that play a significant role in ensuring the longevity and performance of engines. Their resistance to a wide range of oils, fuels, and chemicals makes them indispensable in various industries, from automotive to marine to industrial applications. By effectively sealing the oil pump, these seals prevent leaks, maintain oil pressure, and protect the engine from premature wear and tear.

Given their importance, it's clear that oil pump seals are more than just a minor part of the engine—they are an unsung hero in the world of engine technology. Their ability to withstand complex chemical environments, resist corrosion, and endure high temperatures makes them one of the durable and essential components in modern engines. When properly selected and maintained, oil pump seals ensure smooth engine operation, reducing the likelihood of expensive repairs and enhancing the overall performance and durability of the engine.

By understanding the significance of oil pump seals and their critical role in engine efficiency, we can appreciate how these simple, yet highly effective components contribute to the longevity of machines and vehicles worldwide.