+86-576-88024290

Search

20 02, 2026

Press & Media

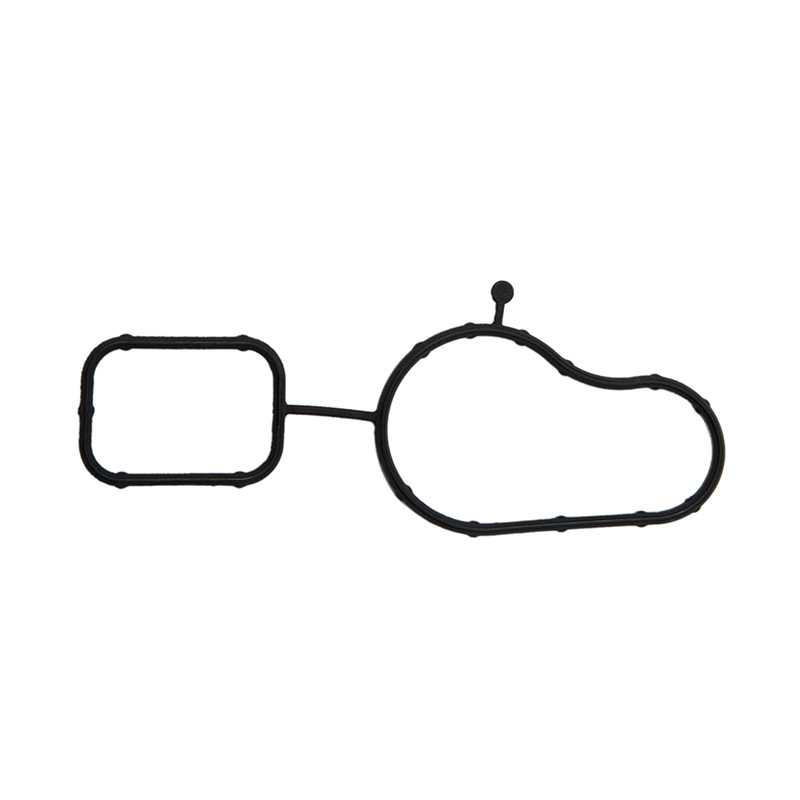

Open a vehicle hood, and attention usually shifts toward visible mechanical structures. Yet deep within the filtration assembly sits a small ring-shaped element quietly influencing lubrication stability — the Automobile Oil Filter Seals. Though compact, its presence shapes how efficiently oil travels through the engine.

When oil escapes or outside particles enter the system, internal friction may gradually rise. Over-extended operation cycles, this can influence engine smoothness. Because of this, engineers often treat Automobile Oil Filter Seals as foundational rather than optional hardware.

Instead of reacting to leakage after it appears, many automotive suppliers now focus on proactive sealing strategies during production.

Lubrication depends on controlled flow. Oil must circulate fast enough to cool moving parts while remaining contained within designated channels. The circular geometry of Automobile Oil Filter Seals allows uniform pressure distribution once compressed between metal surfaces.

Think of the seal as a dynamic barrier rather than a static ring. It adapts to vibration, responds to thermal expansion, and maintains contact despite ongoing mechanical motion.

When these conditions align, engines tend to operate with fewer unexpected interruptions.

Not all sealing compounds behave the same under stress. The development of Automobile Oil Filter Seals has moved beyond basic rubber, incorporating engineered polymers tailored for modern engines.

A seal must compress enough to block gaps without deforming excessively. Achieving this balance requires precise molding practices. Manufacturers producing Automobile Oil Filter Seals often rely on controlled curing processes that support shape retention.

Even microscopic irregularities can influence how evenly the seal distributes force. That is why inspection frequently includes laser measurement or automated optical checks.

Consistency at this scale supports predictable installation results — a factor highly valued by automotive assembly lines.

Engines create a demanding environment marked by vibration, temperature swings, and constant exposure to oil additives. The resilience of Automobile Oil Filter Seals becomes especially relevant during cold starts, when material contraction occurs before heat builds.

Later, as temperatures rise, the same seal expands slightly while maintaining surface contact.

This cycle repeats thousands of times across a vehicle’s service life. A well-formulated seal handles these transitions without losing elasticity, supporting smoother lubrication behavior.

For distributors and fleet managers, component reliability often translates into planning stability. Choosing dependable Automobile Oil Filter Seals can influence maintenance timing and reduce unexpected workshop visits.

In these sectors, predictable servicing windows help streamline logistics and workforce scheduling.

Even advanced engineering benefits from careful handling during installation. Professionals typically follow a few simple habits to help Automobile Oil Filter Seals function as intended.

While these steps appear straightforward, they can significantly influence how the seal behaves once pressure builds.

Manufacturing Trends Reshaping Seal Production

Production technology continues to evolve as automotive tolerances become more refined. Factories manufacturing Automobile Oil Filter Seals increasingly integrate automated workflows to support repeatability.

These methods help reduce variation between units — something global buyers often prioritize when sourcing at scale.

When evaluating suppliers, purchasing teams usually consider more than pricing. The broader supply experience matters just as much.

Working with a knowledgeable producer of Automobile Oil Filter Seals often simplifies cross-border logistics and inventory planning.

Automotive manufacturing is gradually aligning with resource-conscious strategies. Longer-lasting Automobile Oil Filter Seals contribute by supporting extended replacement intervals, which may reduce material consumption over time.

Some producers are also examining recyclable packaging and optimized transport methods to improve shipping efficiency.

While the seal itself is small, collective improvements across millions of vehicles can influence broader sustainability goals.

Research teams continue exploring polymer blends that maintain flexibility across wider thermal ranges. Future versions of Automobile Oil Filter Seals may feature enhanced surface textures designed to improve grip against metal interfaces.

Another emerging direction involves predictive quality analytics, where production data helps identify subtle inconsistencies before distribution begins.

Such developments reflect a shift toward smarter component engineering rather than reactive redesign.

Within the layered architecture of an engine, stability often depends on parts that remain out of sight. Automobile Oil Filter Seals illustrate how thoughtful engineering at a small scale can influence broader mechanical harmony.

For manufacturers, parts distributors, and vehicle operators, paying attention to sealing technology is less about reacting to problems and more about supporting uninterrupted performance.

As vehicles continue to evolve, these compact components remain steady contributors to the systems that keep transportation moving forward.